About Conexpo

CONEXPO is North America's largest construction tradeshow representing earthmoving, lifting, mining, utilities, asphalt, aggregates, and concrete. CONEXPO is held every three years in Las Vegas. You can expect to see around 2800 exhibitors showcasing their products and services, around 150 education sessions, and over 120,000 construction professionals and more will attend the show during the week.

IFPE occurs in conjunction with CONEXPO. IFPE showcases the latest innovations and expertise in the fluid power, power transmission, and motion control industries. You can check out TWG's newest innovations at TWG's IFPE Booth #S83459

Experience the power and innovative capabilities of the TWG brands at CONEXPO.

TWG is showcasing many exciting and innovative experiential product demos. You will not want to miss our Greer LMI or CTL Bumper Winch and TWG Mechanical experience. At CONEXPO, TWG is showcasing Greer LMI, Greer Vision, and the newest innovation Greer Intelligence. You can experience Greer LMI and Vision at the TWG Crane Demo. TWG's IFPE Booth #S83459

TWG CONEXPO GREER LMI EXPERIENCE

Greer, a global industry leader of load moment indication, monitoring and load management technology solutions, is once again leading the playing field in LMI innovation. Greer is making significant investments in providing crane and heavy equipment operators with solutions that increase crane efficiency through real-time object video monitoring and object detection technology.

Late last year at the International Construction and Utility Equipment Exposition (ICUEE) conference, Greer launched our new Greer LMI MG6 with an optional TS7 Touch Screen and Greer Vision our real-time video monitoring solution. At CONEXPO 2020 in Las Vegas, Greer is launching Greer Intelligence. Greer Intelligence provides operators with real-time 360-degree object detection.

At CONEXPO, you can interact and demo the new Greer technology solutions. Please stop by our booth #S83459 and see the Greer LMI experience.

Also, we will be holding a Greer LMI education series:

- Tuesday, March 10th at 1:30 p.m.

- Wednesday, March 11th at 1:30 p.m.

- Thursday: March 12th at 1:30 p.m.

CONEXPO FEATURED GREER LMI TECHNOLOGY SOLUTIONS

Greer LMI MG6 w/optional TS7 Touch Screen

The Greer LMI, built with the all-new MG6 and optional TS7 Touch Screen is the most straightforward interface on the market to use with its intuitive menus and screens that reduce operator training time and increase crane productivity. Greer LMI's systems are easily calibrated to your crane's load chart using innovative proprietary technology, ensuring lightning-fast installation and calibration time. What's more, Greer's LMI technology solution is designed and engineered for reliable, predictable performance in the harshest of conditions.

Highlights:

- Intuitive menus and screens reduce operator training time and increase crane productivity.

- Multiple display options available in touch screen or push-button technology.

- Fastest calibration in the market leveraging deep industry experience.

- Customizable operator alerts; work area definition, boom height, boom angle, and extension.

- Industry-standard monitoring of crane capacity to ensure safe operations.

- Operators can easily customize alerts based on current environmental or job site conditions.

Features:

- Data Logger & Event Recorder

- Out of the box state regulatory compliant.

- USB accessible for easy data retrieval.

- Easy Serviceability

- Lower total cost of ownership (LTCO)

- Transducers are individually replaceable.

- Extended life of equipment.

- Flexible Cab CPU Placement.

- Enhanced Indication Flexibility

- Multiple inputs and outputs for feature enhancements.

- CAN J1939.Greer Vision

- Computer is IP66, display IP66, and camera IP67

Greer TS7 Display

Highlights:

- Optically-bonded 7-inch LCD designed for harsh environments.

- High-brightness screen for full sunlight viewability.

- Glass display surface offers enhanced clarity and strength.

- CAN-based display with rich, full-color graphics.

Features:

- For rugged applications of all sizes, the TS7 is the perfect fit.

- With a 7-inch LCD screen, operators can get the full view of their equipment on a single all-weather display.

- The TS7 is easily viewed in full sunlight and contains an optically bonded LCD inside its IP67-rated case to keep it safe in all-weather environments.

- Equipped with a high-speed processor, the TS7 delivers seamless graphics, animations, and video playback for a rich user experience.

- The TS7 is available in glass-front, glove-friendly touchscreen and non-touchscreen models to suit the needs of your application

Specs:

- Processor: Renesas® R-Car M2 with Arm® Cortex®-A15 dual-core processor @ 1.5 GHz (32-bit)

- Screen size: 7-inch (178 mm)

- Surface: Anti-glare

- Display type: LVDS TFT LCD with LED backlight, 16-bit color

- Connectors: (2) AMPSEAL 23 pin (main) (1) M12 5 pin [Ethernet] (optional) (1) M12 3 pin (optional) (1) USB pigtail (1) Antenna connector pigtail (optional)

- Video inputs: (4) NTSC/PAL (single channel viewable), PoE camera compatability coming in Summer 2020

- Audio outputs: (2) Line Out (optional) (1) Subwoofer (optional)

- CAN (2) CAN 2.0B according to ISO-11898-2; J1939 and proprietary messaging

- Serial: (1) RS-485 serial (Modbus) USB USB 2.0 full speed host

- Ethernet: 1 X Ethernet 10/100 Base-T (optional) WI-FI 802.11 b/g radio (optional)

- Bluetooth: Fully integrated Bluetooth 2.1, class 1 (optional)

- Inputs: (3) Analog 0–5 VDC, 4-20 mA, resistive, 10-bit resolution (5) Discrete digital, active-high (1) Frequency: in (2Hz–10kHz) 5V pk-pk min, 120V pk-pk max

- Outputs: (1) 500 mA switched low-side (1) Frequency output (2Hz–3KHz)

- Operating temperature: -40°C to +85°C (-40°F to +185°F)

- Storage temperature: -40°C to +85°C (-40°F to +185°F)

- Protection: IP66 and IP67, front and back, for outdoor use

- Vibration: 7.86 Grms (5–2000Hz), 3 axes SHOCK ±50G in 3 axes

- EMC/EMI SAE J1113, ISO 13766, CE per 2014/30/EU

Greer Intelligence

TWG is launching Greer Intelligence at CONEXPO. Greer Intelligence is a blind-spot monitoring, multi-object detection solution that provides crane, heavy equipment, and recovery operators across various industries a real-time 360-degree view of their job site surroundings. You can see Greer Intelligence in action at our CONEXPO Booth: S83459.

Highlights:

- Greer Intelligence is a blind-spot monitoring, multi-object detection solution that provides crane, heavy equipment, and recovery operators across various industries a real-time 360-degree view of their job site surroundings.

- Fully integrated with our LMI and datalogger and provides real-time video playback of events and alerts.

- Available on our TS7 or Element II display models.

- Designed with rugged hardware for the harshest environments.

Features:

- Smart Visual Intelligence

- Real-time monitoring to ensure efficient operations

- Blindspot detection

- Dynamic multi-directional monitoring

- High definition recognition

- Up to 12 cameras

- Multiple inputs and outputs for feature enhancements

- Multiple customization options available

- Interfaces such as CAN with J1939 or CAN

- Computer is IP66, display IP66, and camera IP67

- Flexible integration

- Ultra-compact and easy to install

- Rugged hardware for the harshest environments

Greer Vision

Greer, the global industry leader of real-time mobile industrial video monitoring. Greer’s video monitoring system Is configurable to provide a 360-degree view that continuously monitors the job site and provides vital data, and crane operators need to maximize efficiency and awareness. State of the art technology offers integrated video output paired seamlessly with Greer LMI or provided as a stand-alone option. Greer's multi-camera solution increases operator productivity, optimizes machine output, and enhance crane operation. Greer’s rugged display and cameras are engineered for predictable performance, regardless of the weather conditions.

Highlights:

- Easy operator installation.

- Immediate uptime, no training required.

- Easily embedded into Greer’s LMI touch screen.

- Greer’s Intuitive integrated interface increases crane productivity.

- Multiple display options available in touch screen.

- 360-degree view to ensure safe operations.

Greer Wind Speed Indicator

Greer WSI with ULTRASONIC sensors provides you with the most reliable wind speed indicator on the market —allowing continuous measurement of wind speed and direction. Greer WSI is durable and rugged as it has no moving parts and has a compact waterproof footprint. Reliability and performance, along with no moving parts, makes it a natural choice while reducing the total cost of ownership and downtime.

Highlights:

- Ultrasonic wind readings

- Apparent wind speed

- Waterproof

- Output: Wireless or Wired available

Specifications:

Wind Speed:

• Range: 0-90mph

• Resolution: +/- 0.2 mph at 22 mph

Wind Direction:

• Range: 0 - 360º

Power:

• Battery powered for wireless system.

Dimensions:

• Diameter: 2.75 in*

• Height: 2.25 in*

*Does not contain dimensions of other system parts.

GREER LMI TECHNOLOGY SOLUTIONS

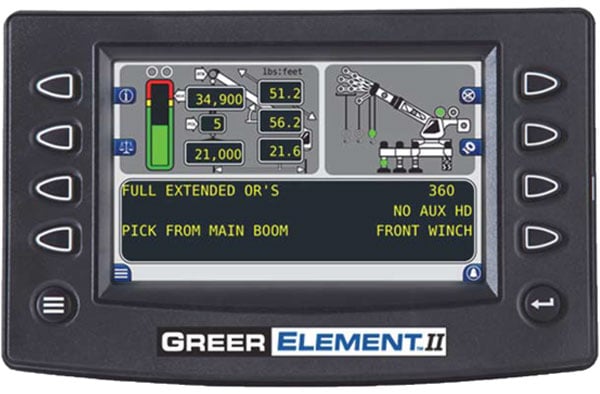

Greer Element II Display

Greer Element II™ is the industry’s only crane monitoring display that offers feature-rich capabilities, multiple screens, and language conversions to help operators work safer and smarter. Greer Element II is standard with a WVGA graphics display system for sharper, clearer images. They are optically bonded with a glare free 7” screen. J1939 CAN output enabled.

Highlights:

- Unlike other monitoring displays, the Element II offers true VGA graphics to view real-time information sharper and easier.

- Dynamic screens enable operators to switch between multiple windows and offers fingertip access to work area definition (WAD), crane configuration, diagnostics, gauge readings, and other critical data from crane sensors.

- But perhaps the most impressive capabilities are the Element’s language and units of measure. Now, operators can choose from a multiple language menu, and even select between Imperial or Metric units. The Greer Element II is customer-engineered to provide intuitive functionality and expandable capability as more sensors are added.

- The Element II is just one value-added component in the Greer family of load moment indicator systems. Greer’s load moment indicator systems feature our exclusive FastCal technology to deliver the fastest calibration time in the industry.

- Now, Greer LMIs automatically transmit rated capacity, actual load, percent of rated capacity, load radius, boom angle, boom length, and crane configuration data to our new Element crane monitoring display.

- Familiar Functionality. The Element II’s learning curve is so low any experienced operator will be up to speed in minutes. Visual design and functionality mimic the legacy display for a smooth transition.

- Enhanced capabilities open the door for new features, putting even more real-time, vital information at an operator’s fingertips.

- For more information about the Greer Element II and other electronic monitoring components, please contact a TWG sales representative.

Features:

- VGA graphics display system for sharper, clearer images

- Attractive 7” screen

- Expanded capabilities with same ease of use

- Multiple screens to view WAD, crane configuration, diagnostics, gauge readings and other sensor data

- Customizable configuration

- Multiple language menu

- Imperial and Metric units

- CANJ1939 and CAN Open enabled

- Entire display is IP67 waterproof

- Visual and audible alarms

- Lighted-path graphics

- Sun visor for easier viewing in bright light, optional

- Dash-mountable

Greer Insight Display

Greer Insight™ is the industry’s only monitoring display designed for boom trucks, that offers the feature-rich capabilities and high-resolution VGA graphics to help operators work smarter.

Highlights:

- Greer Insight offers multiple screens with a simple, intuitive display design and customizable configurability for quick start-up and easy use.

- Operators enjoy an 8-button display to map for applications, and fingertip access to work area definition (WAD), crane configuration, diagnostics, gauge readings, and other critical data from crane sensors.

- The entire display is IP67 waterproof, making it ideal for year-round use even in harsh environments.

- But perhaps the most impressive capabilities are the Insight’s language and units of measure. Now, operators can choose from a multiple language menu, and even switch between Imperial or Metric units. Greer Insight is small, compact, and powerful.

- The Insight’s learning curve is so low any experienced operator will be up to speed in minutes.

- The Insight is just one value-added component in the Greer family of rated-capacity indicator systems.

- Greer’s rated-capacity indicator systems feature our exclusive FastCal technology to deliver the industry’s fastest calibration time.

- Now, Greer LMIs automatically transmit rated capacity, actual load, percent of rated capacity, load radius, boom angle, boom length, and crane configuration data to our new Insight monitoring display.

For more information about the Greer Insight and other electronic monitoring components, please contact a TWG sales representative.

Features:

- VGA graphics display system for sharper, clearer images

- Attractive 4.4” screen

- Intuitive design for quick start-up and easy use

- Multiple screens to view WAD, crane configuration, diagnostics, gauge readings and other sensor data

- Customizable configuration with minimal keystrokes

- Multiple language menu with ability to add and display additional languages

- Imperial and Metric units

- CANJ1939 and CAN Open enabled

- Ram-mount or in-dash capable

- Visual and audible alarms

- Optically bonded for optimal outdoor viewing

- Entire display is IP67 waterproof

Greer Anti-Two-Block System & Switches

Greer markets a comprehensive line of ATB switches for hydraulic cranes. Greer offers switches that mount at either a thirty-degree angle or horizontal. Hard-wired (black housing) and Radio (white housing) switches are offered in a wide variety of configurations for virtually every ATB application.

Greer ATB switches are available for main, jib auxiliary, and rooster installations. Switches come with cables, “MS” moisture resistant connectors, a weld plate for mounting switches, a selector switch box on some models, along with installation instructions. Jib cable extensions may be ordered in lengths to match the main or jib sections.

All Greer switches have undergone extensive field testing to maintain their reputation for high product reliability. Besides, the standard product line, the Greer Company, also offers custom switches developed for individual customer applications.

- Hardwired Anti Two-Block Systems: Model BB-58 and 509

- Multifunction two-block warning systems for mobile hydraulic cranes.

- Audible and visual alarms.

- Models included a 10-amp ready to operate an optional motion-cut solenoid.

- Anti-Two-Block Switches

- A wide range of configurations for main hoist, auxiliary hoist and jib applications.

- Simple, rugged design.

- Reliable and maintenance free.

About Tulsa Winch Group

Around the globe, TWG’s seven distinct brands receive recognition for superior product performance, custom solutions, and innovative capability. Our customers know DP Winch®, Gear Products, Greer®, LANTEC®, Pullmaster®, Rufnek® and Tulsa Winch® by the vital role they play in the energy, infrastructure and recovery markets. TWG engineers and manufactures industry-specific winches, hoists, gear drives, hydraulic pump drives, slewing ring bearings, and monitoring electronics for energy, infrastructure, recovery, marine, and natural resource markets worldwide. The breadth and depth of our gearing solutions and electronic monitoring technology outperform under some of the most demanding conditions on earth.

TWG’s capabilities include two world-class manufacturing centers where we deploy superior design and engineering solutions to deliver customized gearing and electronics solutions. Our ability to integrate data-capture technology into our product lines has made us an industry innovator and a market leader. Our North America headquarters is in Jenks, Oklahoma. Here, the combined operations of DP Winch, Greer, Gear Products, Rufnek, and Tulsa Winch provide a lean, innovative, streamlined approach to next-generation product development and problem-solving. In Surrey, British Columbia, we manufacture our world-renowned Pullmaster and LANTEC solutions.

Tulsa Winch Group (TWG) Markets

TWG Energy Market

Equipment operators trust TWG’s worm gear and planetary winches, hoists, rotation drives, gear reducers, and electronic monitoring solutions every day on their equipment and truck fleets that service the onshore and offshore oil and gas industry, including drilling and production.

TWG Infrastructure Market

TWG’s worm gear and planetary winches, hoists, rotation drives, gear reducers, swing drives, auger drives, slewing ring bearings, hydraulic pump drives, rotators, and electronic monitoring solutions are used on cranes and by heavy equipment that operators that serve the construction and mining industry, light and heavy industrial applications, utility work, foundation drilling, and dredging operations.

TWG Recovery Market

TWG’s world-renowned worm gear and planetary winches, bumper winch kits, hoists, rotation drives, gear reducers, and electronic monitoring solutions are used on cranes, wreckers, and heavy equipment that serve government, towing, marine, and forestry.

TWG Marine Market

TWG’s planetary hoists and winches, rotation drives, SRB’s, swing drive and gear reducers, hydraulic pump drives are used on fishing and research vessels, shrimp boats, tuna boats, fishing trollers, workboat, barges, dredges, tug-boats, and marsh buggies.

TWG Natural Resource Market

Equipment operators use TWG’s worm gear and planetary winches, hoists, rotation drives, gear reducers for pipe layers, feller-bunchers, skidders, forwarder’s, harvesters, mulchers, yarder systems, blast hole drills, water well drills, rock crushers, and rock breakers serving the forestry, pipelayer and the mining industry.

Tulsa Winch Group (TWG) Customers

TWG is dedicated to providing the best performing industrial and electronic solutions for our Original Equipment Manufacturers (OEMs), distributors and fleet customers of cranes, trucks, industrial platforms, and heavy equipment throughout the world. Our teams are focused on providing excellent customer and partner experiences. We work closely with our customers to develop innovative gearing and electronic monitoring solutions that enhance equipment performance, minimize equipment risk, and create added value for owners and operators.